About the Technology of Centre Grinding

The Problem

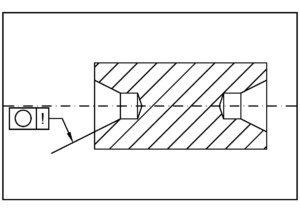

Axially symmetrical workpieces are machined between the tips. The centre holes are placed front-ended into the part. Hence the position of the two centre holes defines the axis of the workpiece. The position is not defined in unround centres.

It is irrelevant whether the manufacturing process takes place on a cylindrical grinding machine or a lathe. Unround centre problems occur in all manufacturing processes in which the workpiece has to be handled between the tips.

The roundness error in the centre can be measured due to a higher misalignment between the centres and the ground shoulder. Since the topology of the unround center can be of any size or shape, the misalignment can be anywhere between 0 and the roundness error of the centre.

Why is a Precise, Round Centre needed?

A high roundness error in the centre means that the position of the workpiece on the centering point is not defined during the machining process. This is shown through at least four characteristics:

1. The Part on the Tip

In the unround centre the workpiece can move around on the tip. It literally "slips" around on the tip within the centering hole. Hence the roundness error of the centre is process-reflected and shown on the outside.

2. Reproducibility & Process Capability

The spread of radial runout increases during series production. The process capability – the ratio between the permissible tolerance and the spread – is fading rapidly.

3. Quality Management

The following quality check of the tips will show that the position of work piece is not exactly the same as it was during the manufacturing process. The measurement of the runout is therefore not correct and also not reproducible. In the worst case, it will measure false. An incorrectly measured good work piece is mostly being scrapped.

4. Multiple Reoccurrances of the Central Roundness Error

Drive technology is clearly going towards lightweight constructions. This means that the workpieces become thinner-walled, hence more fragile during the process. The thin-walled workpiece can be shaped with a high pressure on the centre. The roundness error of the centre is shown on the outside. If the outside is then ground round, the part is round. If the tips are moved out the work piece, it can release.

The Klein Centre Grinding Machine ZSS or ZSU can solve the problem.